Design and implementation of industrial systems

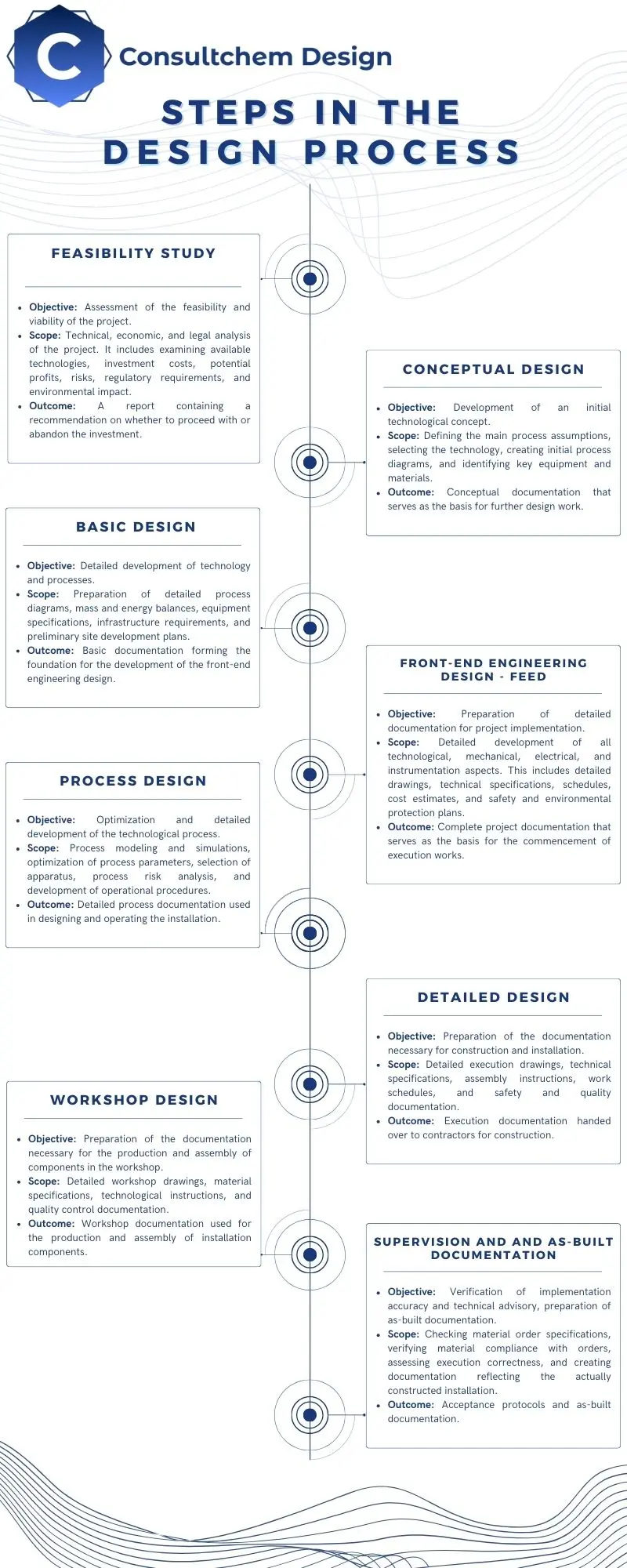

The following stages can be detailed in the design process of a new manufacturing facility:

- conceptual phase;

- construction design;

- technical design;

- detailed design;

- Sometimes it is also necessary to make workshop designs of some elements of the system or structure allowing the work to be ordered to specialised manufacturing workshops.

Design of technological systems

Consultchem Design specialises in the design of technological systems for the chemical, food, biotechnology and pharmaceutical industries. The design process can usually be divided into:

conceptual design - allows an initial selection of appropriate equipment and carrying out energy and material balances for the operation of the system; during the conceptual design the requirements of the production system are specified in terms of construction and the required auxiliary systems such as: compressed air and nitrogen systems, process water system, CIP, process steam, allowing for a smooth transition to the subsequent phases of the project;

basic design;

detailed design.

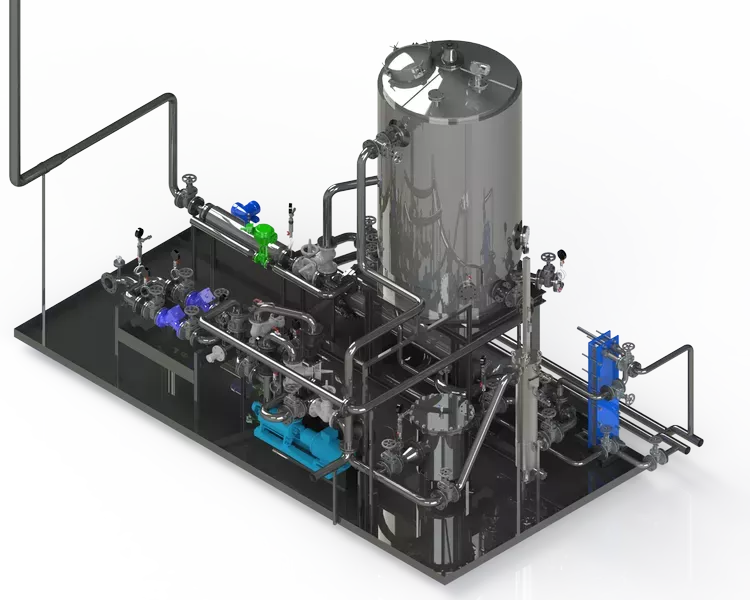

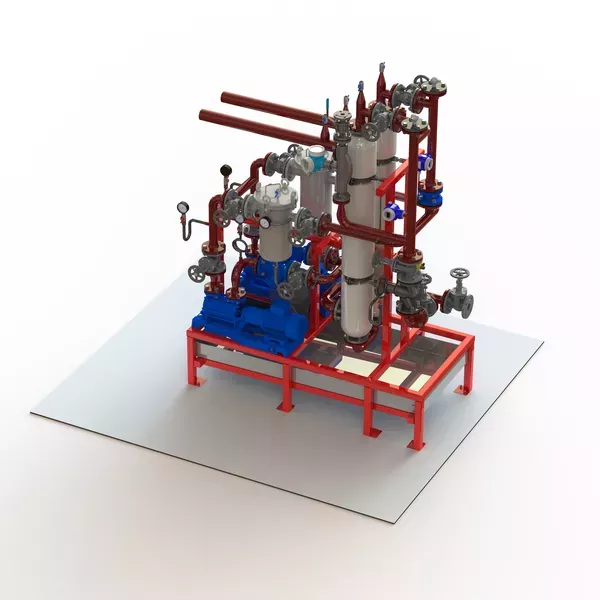

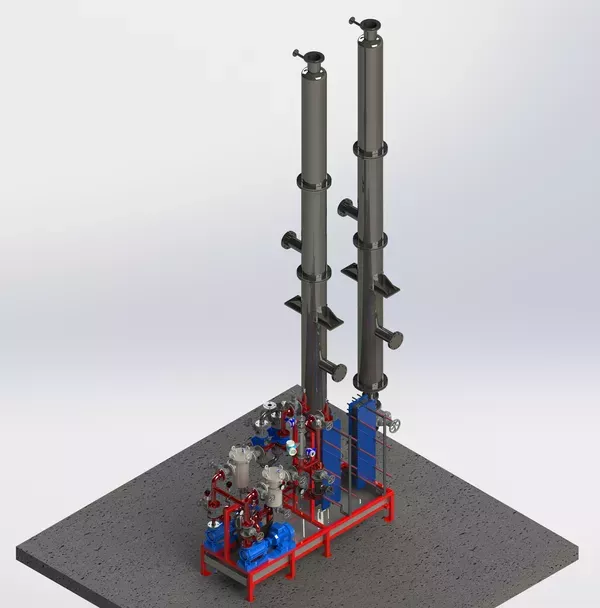

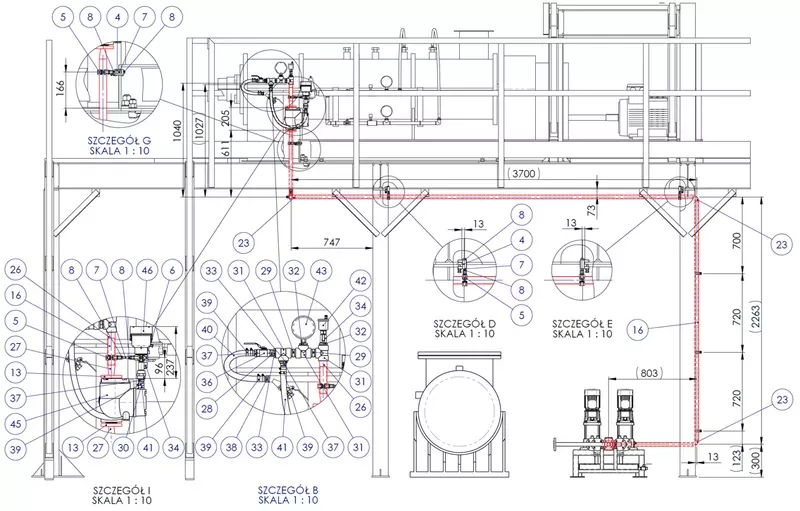

3D modelling

All the systems designed by us are made using a 3D CAD environment. It enables easy verification of the proposed solutions and minimises the risk of clashes with existing systems at the assembly stage. As part of the design documentation provided, the investor receives a full 3D model of the designed system from us.

Process balancing and CFD/MES simulations

Some of the unusual design solutions require verification using numerical methods. Consulchem Design has a team of designers with experience in numerical simulations of industrial processes documented by scientific publications. Using CFD software supplemented with our own models, we conduct simulations of both the flow and the chemical reactions or phase transformations taking place in the system. For the static analysis of structural elements, we use FEM analysis.

Testing, explosion hazard assessment

In many cases, the investor may not have the physical and chemical data of the media necessary to design the system and select the devices. In such cases, the need for additional measurements arises. Consultchem Design offers the following tests and measurements:

determination of the viscosity of the medium;

fitting rheological models;

measurements of explosion parameters

measurements of particle size distributions;

chromatographic analyses;

In the case of potentially explosive media in the process, we carry out an explosion risk assessment, which determines the relevant explosion risk zones and specifies the requirements for the construction of devices and C&I equipment.

In the project is carried out in an existing building or existing devices are used, an inventory must be carried out in order to adjust the designed systems and determine the necessary modifications to adapt to current regulations. We carry out an inventory in terms of building structures, electrical and sanitary systems and a mechanical inventory of existing systems and devices. We also offer the possibility of using 3D scanning for inventory purposes.